MBB C 2000 L

TAIL LIFT

- Optimum ratio of dead weight to payload = greater transport capacity

- Lifting capacity of 2,000 kg with 750 mm load distance

- Variable lifting mechanism with five available lifting arm lengths for all common attachment situations

- Design with aluminium or steel platform

- Wide range of options and equipment variants

Experience The Product Features

PLATFORM STANDARD

- AluLite 30/40/40S – platform

- Ground rollers

- Warning flags red/white or black/yellow

- LED warning lights

- Protection bars for warning lights, pair

- Roll protection

OUTSIDE

- Aluminium platform with wet-painted rearside, with or without tip (in a RAL colour)

- Aluminium platform anodised (up to 2000mm height)

LIFTING GEAR STANDARD

- Cylinders with protection bellows and tubes

- All steel components in KTL

- Vehicle specific mounting brackets

- Lifting gear powder-coated (in RAL9011 or NOVA grey)

- Provision for ball-head coupling installation MBB PTC 750 L / S & PTC 1000 LLW (incl. central support)

OTHER OPTIONS AND ACCESSORIES

- Seal kit system L with MBB profile, 4 sides

- Safety gate, A-shape A1100, in RAL-color e.g. 1023, piece (not for AluLite)

- Safety gate, P-shape, in RAL-color e.g. 1023, piece, left or right (not for AluLite)

Technical Data

| Lifting capacity | 2000 kg |

| Main beam | 180 x 180 mm |

| Lifting gear hydraulics | 2 lifting cylinder / 2 tilting cylinder |

| Platform overlap with floor | – 63 mm |

| Lift arm pitch /Lift arm length | 1300 mm |

| Load centre – lengthwise | 750 mm |

| Load centre – across center | Central 50% of rated load on one side |

| Inclination angle of the platform | +90° to -10° |

| Platform type | alu | alu |

| Platform width | 2500 | 2500 |

| platform height | 1800 | 2100 |

| Dead Weight | 517 | 539 |

| Dead Weight | – | – |

The specified weights apply to the lightest platforms of the corresponding height. Dimensions may vary. Subject to technical changes, errors and translation mistakes.

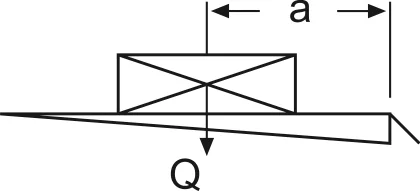

| a (mm) | Q (kg) |

| 750 | 2000 |

| 900 | 1650 |

| 1100 | 1300 |

| 1600 | 950 |

| 2400 | 600 |

FEASIBILITY STUDY

Webtool for automatic feasibility study for C- Type Lifts

Here you can create your feasibility study drawing online. For an extensive range of vehicles, quickly and without obligation

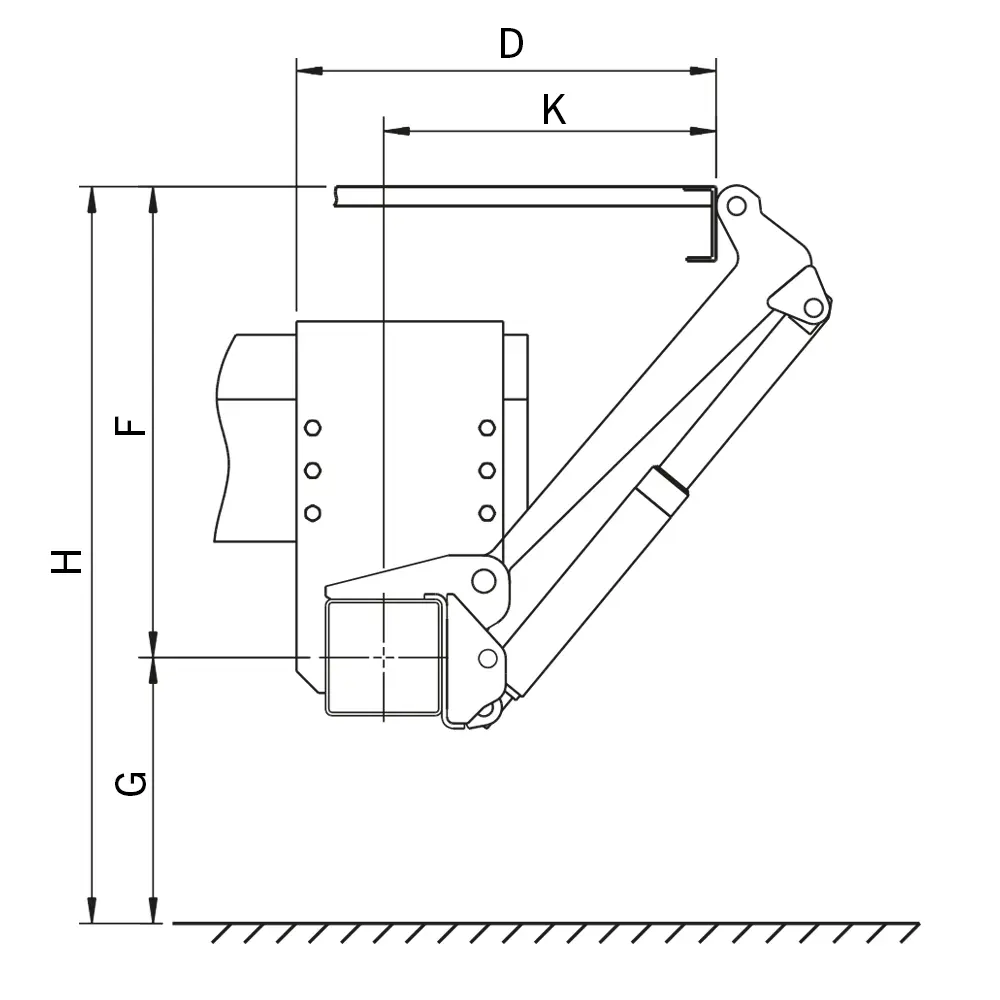

| Lift arms (in mm) | 750 | 800 | 850 | 950 |

| H (max.) Loading height unloaded | 1340 | 1416 | 1505 | 1657 |

| H (min.) Loading height loaded | 1127 | 1165 | 1204 | 1281 |

| F (max.) Middle of main beam to upper edge of loading floor | 858 | 904 | 967 | 1061 |

| K (min.) at dimension F (max.) | 413 | 434 | 410 | 444 |

| D (min.) Installation space (min.) | 563 | 584 | 560 | 594 |

| D (max.) Installation space (max.) | 752 | 785 | 816 | 880 |

| F (min.) | 742 | 780 | 819 | 896 |

| K (max.) at dimension F (min.) | 602 | 635 | 666 | 730 |